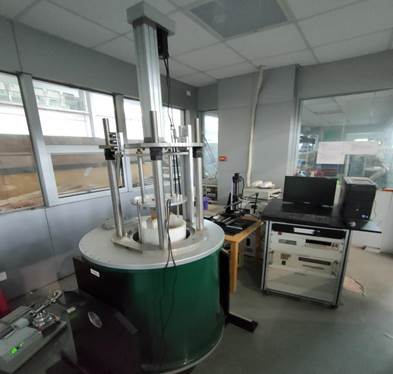

High-speed wheel/rail friction and wear testing rig

This high-speed wheel/rail simulation facility is composed of a simulation wheel roller, simulation rail roller, driving system of attack angle, excitation system, DC traction motor, diaphragm thimble, gear shift housing, virtual wheel installation, etc. Functions:This unit can simulate wheel/rail behavior under high-speed conditions of up to 350 km/h with an axle loading capacity of 30 tons...